GD HS 001A

Goldconn

| Material: | |

|---|---|

| Manufacturing process: | |

| Finish: | |

| Availability: | |

| Quantity: | |

Copper Skiving fin heatsink

The Skived fin, also known as skiving technology, simply takes an entire piece of aluminum or copper and use special skived machine to cut out fins with standard spacing and a certain thickness and height. Goldconn Technologies lead multi-inlet technology and pushs the manufactoring limits to work out 100 micron fins with 120 micron channels and maximizing the coefficient of heat transfer in customer's high liquid cooling system.

Goldconn uses the TOP quality copper C1100 which provides highest conductivity copper for the best heat transfer, with nice flatness 0.01-0.05Max and good roughness on surface to fit customer's requirement..

Product detailed specification as following

| Material | Copper C1100 |

| Tolerance | +/-0.15mm |

| Surface Treatment | Polishing+passivation |

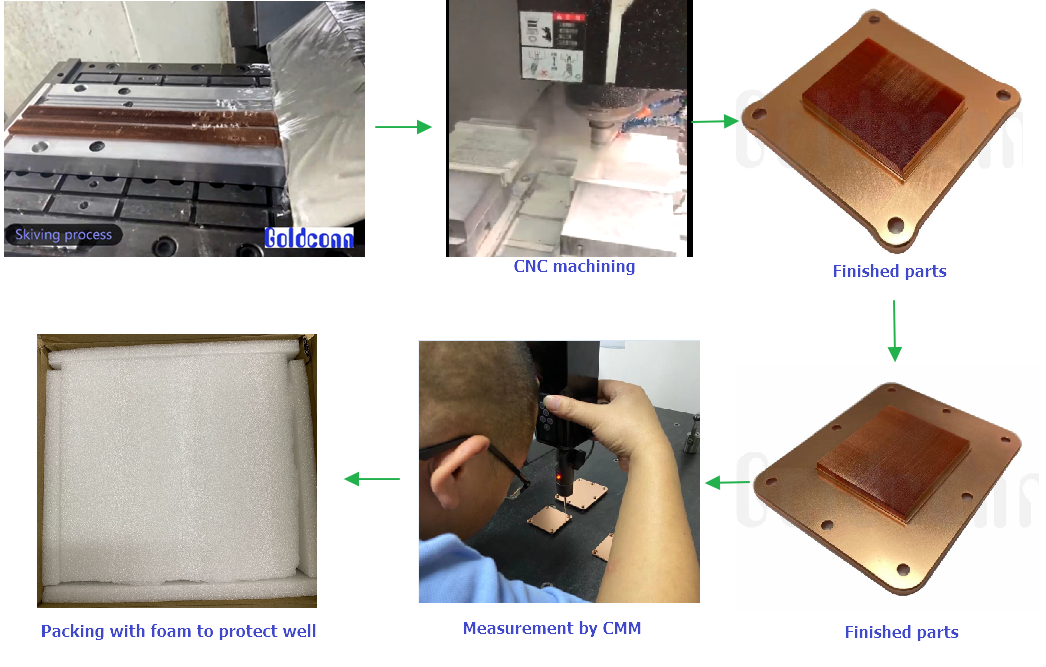

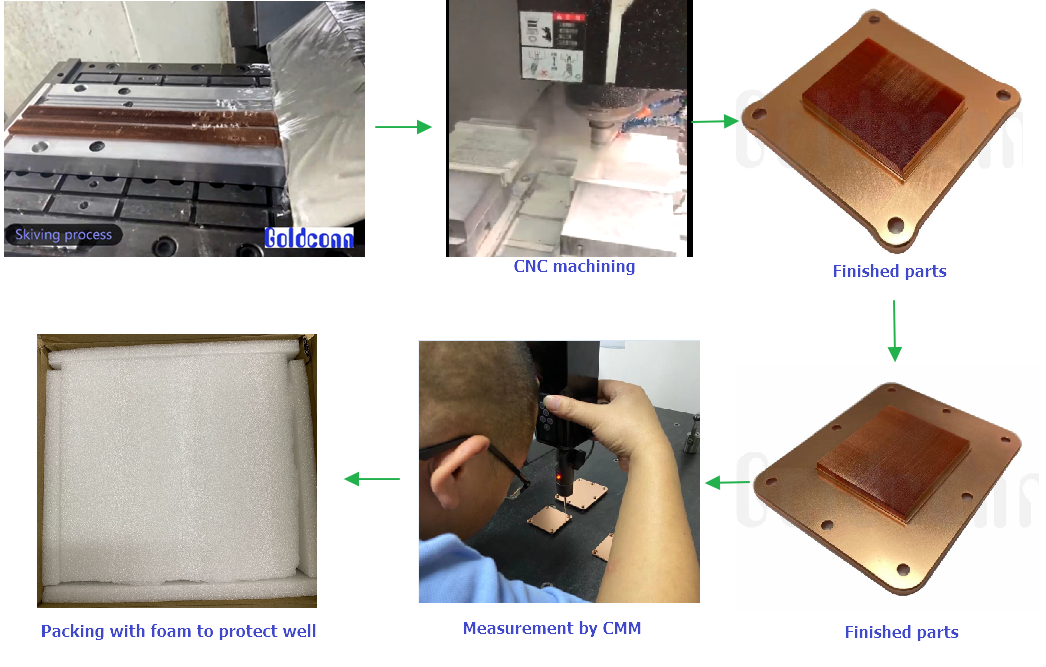

| Main Process | Skiving fin=> cutting=>CNC machining =>Polishing=>passivation=>inspection |

| Quality Control | Strictly Quality control in the whole process, from material to packing |

| 3D projector, caliper, Coordinate-measuring machine | |

| Application | Liquid cooling system |

Skived fin heat sink has the following advantages:

(1) Perfect conductivity between base and fins. Because skived fin heat sink is a whole profile without any connection point, which can give full play to the heat dissipation characteristics of the heat sink.

(2) High fin densitie, skived fin process can make the skived fin more thinner and denser, with higher heat transfer efficiency.

(3) Great forced airflow solution, the skived fin processing technology is simpler than other liquid cooled heat sink, with lighter weight and lower cost.

(4) Compared with aluminum extrusion and other processes, skived heatsink is less limited in size and can be made wider, which can be used for heat transfer of machines with large power.

(5) Customized skived fin heat sink does not need expensive tooling which provides greater design flexibility. Instead, each skived fin is cut separately using the same tool which allows for lower tooling costs.

(6) Add a thermal interface material to the skvied fin heatsinks to better connect with your heat source and complete your thermal solution.

Copper Skiving fin heatsink

The Skived fin, also known as skiving technology, simply takes an entire piece of aluminum or copper and use special skived machine to cut out fins with standard spacing and a certain thickness and height. Goldconn Technologies lead multi-inlet technology and pushs the manufactoring limits to work out 100 micron fins with 120 micron channels and maximizing the coefficient of heat transfer in customer's high liquid cooling system.

Goldconn uses the TOP quality copper C1100 which provides highest conductivity copper for the best heat transfer, with nice flatness 0.01-0.05Max and good roughness on surface to fit customer's requirement..

Product detailed specification as following

| Material | Copper C1100 |

| Tolerance | +/-0.15mm |

| Surface Treatment | Polishing+passivation |

| Main Process | Skiving fin=> cutting=>CNC machining =>Polishing=>passivation=>inspection |

| Quality Control | Strictly Quality control in the whole process, from material to packing |

| 3D projector, caliper, Coordinate-measuring machine | |

| Application | Liquid cooling system |

Skived fin heat sink has the following advantages:

(1) Perfect conductivity between base and fins. Because skived fin heat sink is a whole profile without any connection point, which can give full play to the heat dissipation characteristics of the heat sink.

(2) High fin densitie, skived fin process can make the skived fin more thinner and denser, with higher heat transfer efficiency.

(3) Great forced airflow solution, the skived fin processing technology is simpler than other liquid cooled heat sink, with lighter weight and lower cost.

(4) Compared with aluminum extrusion and other processes, skived heatsink is less limited in size and can be made wider, which can be used for heat transfer of machines with large power.

(5) Customized skived fin heat sink does not need expensive tooling which provides greater design flexibility. Instead, each skived fin is cut separately using the same tool which allows for lower tooling costs.

(6) Add a thermal interface material to the skvied fin heatsinks to better connect with your heat source and complete your thermal solution.