Views: 26 Author: Site Editor Publish Time: 2022-09-09 Origin: Site

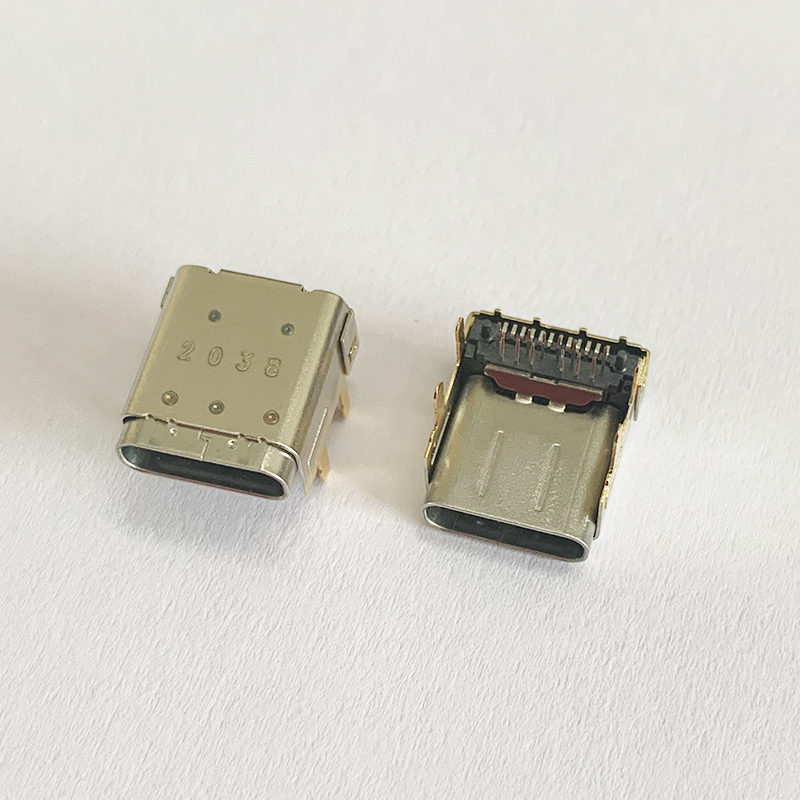

USB connectors were introduced in the mid-1990s and have since evolved in size, shape, and data and power transfer capabilities. Today, the latest physical standard is Type C. In addition to greater bandwidth and bi-directionality, and reversibility, this latest iteration is capable of significantly higher power transfer than previous generations.

Because of its powerful performance and broad applicability, USB Type C is increasingly being used in many electronic products. How should engineers choose the correct USB Type C connector for their products when developing and designing electronics projects? Here follow USB Type C manufacturer Goldconn to understand what factors need to be considered when choosing a connector.

The first thing to consider is how much power transfer you need to support with the connector you select. This will ensure that the selected connector is correctly specified to handle the system's maximum voltage and current ratings so that the connector and associated components are not damaged.

Other considerations include mounting method (through-hole, surface mount, cable mount, etc.), desired orientation in the application, size and dimensional requirements, IP rating, etc.

What factors should an engineer consider when making a specific selection of a USB Type C connector?

Typically, USB connectors are defined by three different but related standards: physical connector, data transfer protocol, and power transfer.

The latest USB Type C standard defines only the physical connector, which can support data transfer speeds of up to 20 Gbit/s as defined in the USB 3.2 data transfer standard and power transfer of up to 100 W as defined in USB Power Delivery (PD) 3.0.

Despite the high degree of standardization, there are still differences in voltage and current capabilities and data rates for USB Type C connectors, so it is essential to verify that the connector specifications meet your system requirements. Other considerations will again come down to the mounting method, orientation, IP rating, etc.

What are the benefits of using USB Type C connectors for power applications compared to other connectors?

Benefits of using USB Type C

In addition to the 16 data transfer pins, the USB Type C connector contains 4 power pins and 4 ground pins, enabling up to 100 W of power capability. This makes USB Type C a viable option for many applications that require higher power, even when data transfer is not required, and it can replace standard DC power connectors.

The most significant benefit of using USB as a power supply method is standardization. USB connectors have become ubiquitous, and the convenience of using a single, off-the-shelf cable type for many different products is beautiful to end users. OEMs also benefit from a stable supply chain, as USB connectors are easy to find, and their standardization ensures a degree of interoperability. This simplified design integration is supported by a smaller package size, high reliability, and longer service life with a 10,000 mating cycle rating than many barrel connectors.

Limitations of USB Type C Connectors

Each connector or component will have its advantages and limitations. For USB Type C connectors and their 100 W power transfer limitations, USB Type C connectors are simply unsuitable for applications requiring more than 100 W of power. In addition, the standardized footprint of USB Type-C has benefits in many scenarios, but in some cases, other package types or orientations may be required. This means there is still a place for DC power connectors and more customizable power supply options.

If, after reading the above introduction on how to choose the suitable USB Type C connector, you are still not quite sure how to choose the suitable connector for your project, you can leave a comment or send an email to contact us. Goldconn is a professional USB Type C connector manufacturer. We can provide the most suitable solution according to your project needs! You can also learn more about our Type C customization service through our "Type C Connector Service" page.

Dear friends, We are pleased to invite you to attend PCIM EUROPE 2025 EXHIBITION. Goldconn will be showcasing our latest innovations and technologies at Hall 6, Booth 300, which will be held at the Nuremburg, Germany, from 6th to 8th May 2025.

The Qingming Festival is an important traditional festival in our country.

https://goldconnhk.com

In order to ensure the safety of employees in the operation of equipment, our company will often hold safety production training to enhance employees' safety awareness and operation norms

Many machine parts that are important for repair and replacement are the product of metal fabrication. The importance of metal fabrication in manufacturing and industry cannot be overstated. This process plays an essential role in manufacturing and is often the foundation and support for sheet metal

USB connectors were introduced in the mid-1990s and have since evolved in size, shape, and data and power transfer capabilities. Today, the latest physical standard is Type C. In addition to greater bandwidth and bi-directionality, and reversibility, this latest iteration is capable of significantly

Many people refer to welding and metal fabrication as if they were two different words for the same process. While both processes require the use of metal, the terms are not interchangeable. Metal fabrication can be described as the process of making a product from metal. Welding is usually a part o