Views: 41 Author: Site Editor Publish Time: 2022-09-16 Origin: Site

Many machine parts that are important for repair and replacement are the product of metal fabrication. The importance of metal fabrication in manufacturing and industry cannot be overstated. This process plays an essential role in manufacturing and is often the foundation and support for sheet metal fabrication.

This article will learn about the differences between metal fabrication and sheet metal fabrication.

What is the role of metal fabrication?

Metal fabrication is the construction of metal structures and products used primarily in the construction, mining, and transportation industries. It often involves the entire process from cutting, bending, welding and assembly. The difference between metal fabrication and sheet metal fabrication is in the materials used. Metal fabrication usually begins with basic raw materials, which are often large and thick, including steel, aluminum, and copper. A metal fabricator may manufacture metal products, including metal structures, machinery and parts, and final products.

What is sheet metal fabrication?

Sheet metal fabrication, on the other hand, is the process of cutting, stamping, folding, welding, and assembling flat metal sheets into metal products. Sheet metal fabrication converts flat metal sheets, usually of thin material, by cutting them with a laser, stamping shapes into the metal, or folding the metal into the desired shape. End products may include furniture, fitness equipment, stairwell railings and balusters, parts used in off-road vehicles, and more. Many through-fast machines can perform multiple processes in a single machine with a setup.

What steps are involved in sheet metal and fabrication metal fabrication?

Metal fabrication involves many processes, including, but not limited to, drawing, cutting, bending, and assembly.

The first necessary process in metal fabrication is drawing. Manufacturers typically use applications to express and visualize the desired end product using specifications and dimensions, which are then processed by the machine.

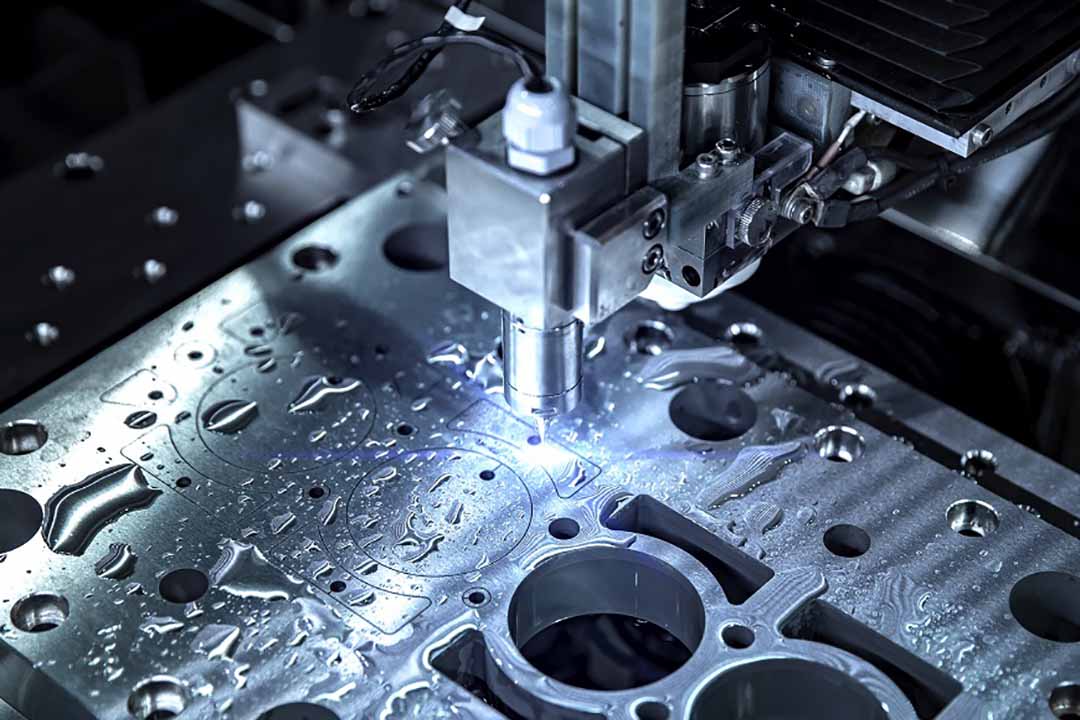

Cutting is usually accomplished by sawing, shearing, or laser cutting. The manufacturing process may also involve using hand-held torches, CNC, and automated laser cutting machines.

Bending can be more manual in manufacturing and may require hammers and hand tools or be more automated through bending machines. Automated bending machines, such as the Trumpf bending machines, automatically position the material sheet to emboss the bending line correctly. Development programming software such as Trumpf's TruTops series brings seamless and efficient programming to CNC-controlled bending machines.

Assembly in metal fabrication involves joining, welding, and riveting metal parts and threaded fasteners.

Advantages of Sheet Metal Fabrication

Sheet metal fabrication processes are ideal for metal parts to support prototyping and production quantities.

▪ Low material waste

▪ Can be cost-effectively scaled to production volumes

▪ Multiple surface treatment options, such as anodizing and powder coating

Sheet metal is a standard manufacturing process for a range of metal parts. The process can support both high-volume commodity products and low-volume, one-of-a-kind applications. Standard sheet metal parts include

▪ Electrical enclosures

▪ Computer electronic parts

▪ Machine housings

▪ Brackets

▪ Cabinets

▪ mounts

▪ home appliances

You can also browse through our "Metal Fabrication" section for more sheet metal styles, If you are interested in learning more about Goldconn's sheet metal fabrication services, you can contact us by message or email. We can provide you with the most professional sheet metal fabrication services.

Dear friends, We are pleased to invite you to attend PCIM EUROPE 2025 EXHIBITION. Goldconn will be showcasing our latest innovations and technologies at Hall 6, Booth 300, which will be held at the Nuremburg, Germany, from 6th to 8th May 2025.

The Qingming Festival is an important traditional festival in our country.

https://goldconnhk.com

In order to ensure the safety of employees in the operation of equipment, our company will often hold safety production training to enhance employees' safety awareness and operation norms

Many machine parts that are important for repair and replacement are the product of metal fabrication. The importance of metal fabrication in manufacturing and industry cannot be overstated. This process plays an essential role in manufacturing and is often the foundation and support for sheet metal

USB connectors were introduced in the mid-1990s and have since evolved in size, shape, and data and power transfer capabilities. Today, the latest physical standard is Type C. In addition to greater bandwidth and bi-directionality, and reversibility, this latest iteration is capable of significantly

Many people refer to welding and metal fabrication as if they were two different words for the same process. While both processes require the use of metal, the terms are not interchangeable. Metal fabrication can be described as the process of making a product from metal. Welding is usually a part o