Views: 8 Author: Site Editor Publish Time: 2022-05-11 Origin: Site

Since the terminal Pin pins are the core of the Type-C connector, the transmission of data and the transmission of current depend on these terminals.

This article will analyze the differences in the number of Type-C connector terminal pins; and the precautions for using the connector. Let's learn more about it!

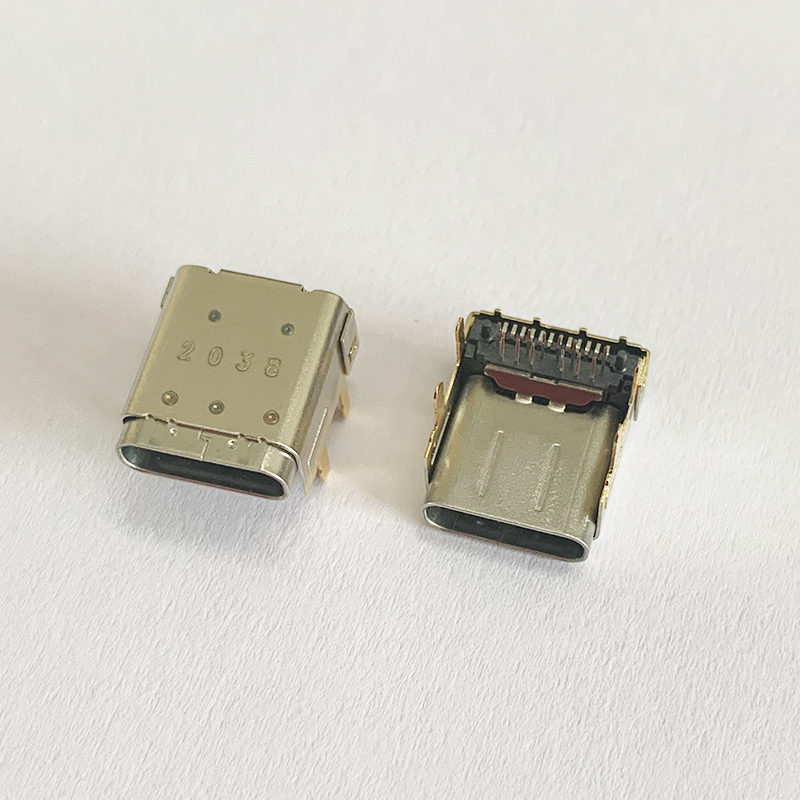

The number of terminal Pin pins in the Type-C connector is enormous. For example, the standard USB connector terminal pin specifications are 6P, 12P, 16P, 14P, 24P, etc. The number of pins on the back of different USB connectors The working function characteristics of the connector is also different.

Type-C connector terminals functional characteristics analysis

The shell of the Type-C connector 24Pin product is made of stainless steel, and the terminal is made of phosphor bronze, which makes it more solid and reliable through the high-precision Stamping process. At the same time, it also supports high-current charging while also supporting data transfer functions.

Therefore, Type-C connector 24Pin products also have high transmission, double-sided support plug, strong compatibility, and other characteristics. Its application is also extensive, such as :

Audio-visual products: MP3, MP4 audio, earphones, Bluetooth products;

Digital products: digital cameras, digital video cameras, etc.;

Communication products: mobile phones, car phones, machines, building equipment, PDAs, etc.;

Security products: video intercoms, monitors, etc.;

Toy products: electronic toys, etc., intelligent toys;

Computer products: cameras, computer motherboards, peripheral computer products;

Fitness equipment: electronic body fat scale, treadmill, etc.;

Medical equipment: sphygmomanometer, clinical thermometer, hospital call system, etc.

1. For the USB connector's long-term use of the case, you need to pay attention to routine maintenance and cleaning. For example, Dust and debris in the internal parts of the connector. These need to be cleaned.

Because when using the Type-C connector, the internal will absorb too much dust and debris directly from the interface. If too much accumulates, it will lead to a decline in the performance of the USB connector; the rear may directly affect the operation of the system circuitry.

2. Type-C connectors are more miniature due to the size interface. If you do not have a technician, please do not disassemble and repair without permission so as not to damage other parts of the USB connector due to improper operation.

It should also be noted that, over time, the Type-C connector internal components aging and damage is generally not convenient to maintain. Even if well-maintained, there are certain safety risks associated with USB connectors, leading to damage caused shortly after use. Therefore, it is recommended to replace the USB connector.

Dear friends, We are pleased to invite you to attend PCIM EUROPE 2025 EXHIBITION. Goldconn will be showcasing our latest innovations and technologies at Hall 6, Booth 300, which will be held at the Nuremburg, Germany, from 6th to 8th May 2025.

The Qingming Festival is an important traditional festival in our country.

https://goldconnhk.com

In order to ensure the safety of employees in the operation of equipment, our company will often hold safety production training to enhance employees' safety awareness and operation norms

Many machine parts that are important for repair and replacement are the product of metal fabrication. The importance of metal fabrication in manufacturing and industry cannot be overstated. This process plays an essential role in manufacturing and is often the foundation and support for sheet metal

USB connectors were introduced in the mid-1990s and have since evolved in size, shape, and data and power transfer capabilities. Today, the latest physical standard is Type C. In addition to greater bandwidth and bi-directionality, and reversibility, this latest iteration is capable of significantly

Many people refer to welding and metal fabrication as if they were two different words for the same process. While both processes require the use of metal, the terms are not interchangeable. Metal fabrication can be described as the process of making a product from metal. Welding is usually a part o