Views: 131 Author: Site Editor Publish Time: 2021-07-12 Origin: Site

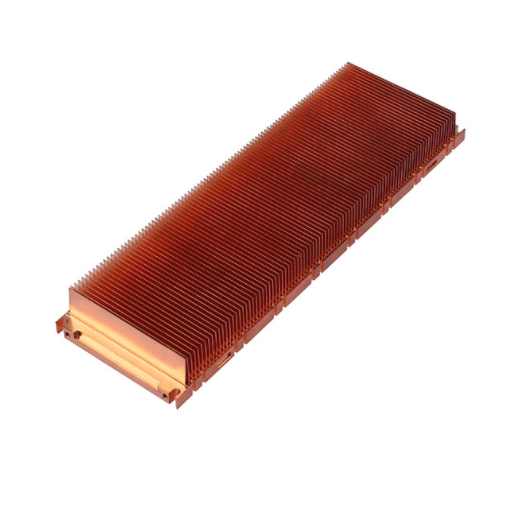

There are many kinds of manufacturing processes for custom heat sinks. According to different product designs of different powers, the heat sink production process will be different. For high power heatsink, skived heat sinks production technology has developed rapidly in recent years, and even replaced the insert heat sink technology in a certain field. So what are the benefits of skived fin heat sinks technology?

The advantages of using skived fin process heat sinks are as follows:

(1) Skived fin heat sink has a higher heat sink density, increases heat dissipation area, and improves heat dissipation performance;

(2) The height of the skived fin heat sink can reach 120mm, which fully meets the production requirements of most heat sinks;

(3) The skived fin heat sink can be made thinner, generally 1.5mm or even 1.0mm, which can make the heat sink lighter;

(4) The skived fin heat sink is shoveled on the prototype material, so the heat dissipation efficiency is not damaged, reaching 100% of the heat dissipation efficiency of the prototype material, and there will be no risk of loosening and falling, improving the reliability of machine operation;

(5) Skived fin heat sink has high compatibility, and the possibility of later processing is also great. It can also cooperate with buried copper pipes and other processes to improve heat dissipation performance;

(6) The skiving heat sink has high production capacity, and the processing cost is easier to control, which is suitable for mass production.

Goldconn is an excellent custom heatsink manufacturer. The high-power shovel technology is widely used in the production of high power heatsink. The products are used in photovoltaic inverters, wind energy converters, and new energy vehicle power battery packs. In terms of production capacity, Goldconn has several large-scale tooth shovel machines to meet the production of large quantities of heat sinks, and the delivery time is guaranteed.

Dear friends, We are pleased to invite you to attend PCIM EUROPE 2025 EXHIBITION. Goldconn will be showcasing our latest innovations and technologies at Hall 6, Booth 300, which will be held at the Nuremburg, Germany, from 6th to 8th May 2025.

The Qingming Festival is an important traditional festival in our country.

https://goldconnhk.com

In order to ensure the safety of employees in the operation of equipment, our company will often hold safety production training to enhance employees' safety awareness and operation norms

Many machine parts that are important for repair and replacement are the product of metal fabrication. The importance of metal fabrication in manufacturing and industry cannot be overstated. This process plays an essential role in manufacturing and is often the foundation and support for sheet metal

USB connectors were introduced in the mid-1990s and have since evolved in size, shape, and data and power transfer capabilities. Today, the latest physical standard is Type C. In addition to greater bandwidth and bi-directionality, and reversibility, this latest iteration is capable of significantly

Many people refer to welding and metal fabrication as if they were two different words for the same process. While both processes require the use of metal, the terms are not interchangeable. Metal fabrication can be described as the process of making a product from metal. Welding is usually a part o